|

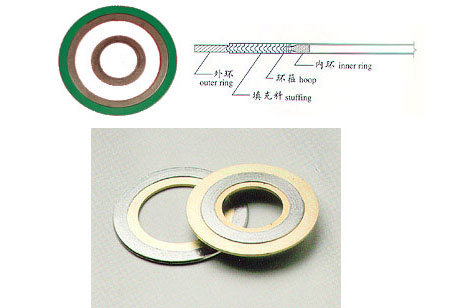

Spiral Wound Gasket

Spiral Wound Gasket is the

ideal gasket in the semi-metallic category. A narrow strip of V-shap metal hoop

is spirally wound under tension with a filler cushion between the lami nation of

the metal and is spot-welded at both ends。

The Spiral Wound Gasket uses expanded graphite tape as the filler material which

provides superb sealability even under severe conditions such us high

temperature, high pressure, cryogenic temperatures, heat cycles, temperature

cycles and so on. Feature

1. Sealing, especially gas sealing, is superior to that of asbestos gaskets.

2. Little deterioration of the filler material at high temperatures,

outstanding long-term sealability even under high temperatures and high

pressures.

3. Sealing remains outstanding even under servere conditions such as pressure

fluctuations and heat cycles.

4. Excellent sealability is maintained making it possible to apply this for

corrosive fluids by selecting the appropriate materials.

5. Outstanding sealing even at cryogenic temperatures.

Service Range:

| fluid |

Maximum service temperature °C |

Maximum service pressure |

| Water type fluids |

450(650) |

Class 2500 |

| Oil type fluids |

450(800) |

Class 1500 |

| Gas type fluids |

450(800) |

Class 1500 |

| Cryogenic temperature fluid |

-240 |

20 Mpa |

|

Spiral Wound Gasket Types:

(1) There are four types: Basic type gasket for motched joint flange;

gasket with

inner ring for raised face flange;gasket with outer ring for smoothing

flat welded flange

and ;gasket with inner and outer rings for smoothing butt welded gasket.

(2) The material:

(A) steel ribbon:304,1Cr18Ni9T(321),316 and 316L,etc.

(B) Ring:mild steel,oCr13,oCr18Ni9,304,316 and 316L,etc.

(C) Non-metal ribbon:flexible graphite,special-purpose asbestos,Teflon

and non-asbestos sheet.

|

|